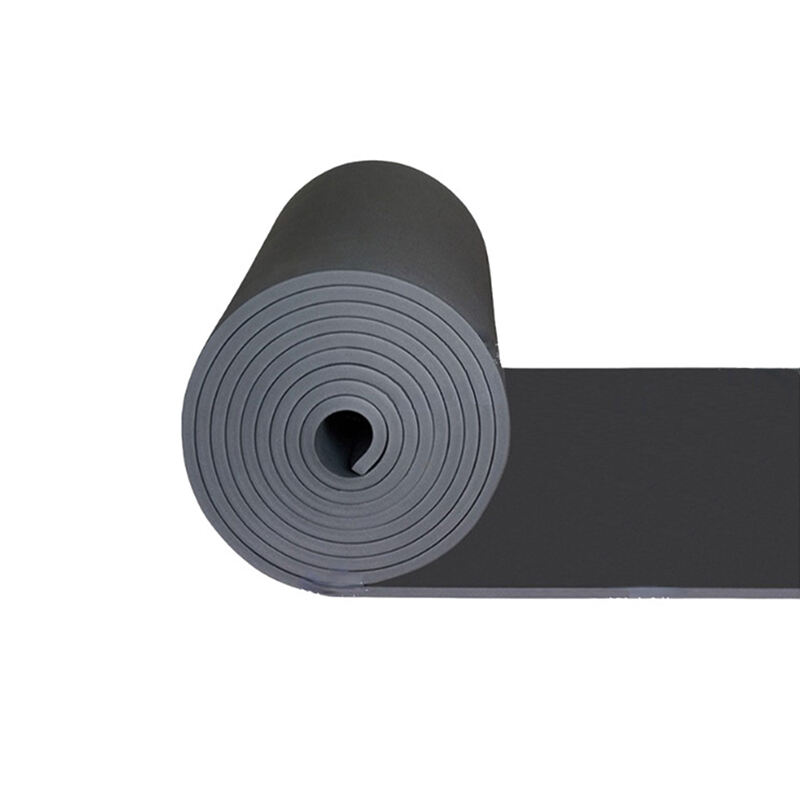

A lot of industries use NBR rubber foam because it is a very popular material. It is perfect for sealing and insulation, it has such great features that make it really useable!

NBR rubber foam is a good quality material that holds up well in a lot of industrial environments. It holds up very well when exposed to chemicals, which is real win. This is the reason why it keeps sturdy and strong for longer, thus a dependable choice in many applications. Furthermore, the foam can also withstand high temperature and that is why it finds so many uses in insulation. Either it is very hot and or extremely cold- here the upmers and NBR Rubber foam are at your service to keep you comfortable as well.

With sealing and insulating being the topic of need within many industries, today's buzzy query seeks to understand more about NBR rubber foam. It is crafted in such a way that it cannot soak up water, therefore enabling the delivery of both air and water away from your feet effectively. This is important in plenty of industrial settings where wear can lead to issues. This foam is very robust and durable, offering an ideal solution for sealing and thermal insulation applications in factories etc. For this reason, companies can trust their goods and equipment to be insulated by NBR rubber foam.

The NBR rubber foam has various crucial characteristics that explained why it is such an ideal material to keep things both warm and quiet. Its greatest use case is to attenuate noise. The foam has a unique structure which allows it to absorb sound, so its used for noise reduction in quite areas like recording studios or inside an office. However, its thermal insulation features are beneficial for the industries that require temperature control. This means NBR rubber foam can be very useful in keeping places like refrigerators or heating systems at the appropriate temperature.

It is also s very flexible material that many suppliers use for producing gaskets and seals of closing the gaps. One model of a Gasket is, an essential part that serves to prevent leaks for example NBR rubber foam. The structural nature of this piping type gives it resistance to oil and moisture which is essential in the field where oily substances are omnipresent. Furthermore, due to their mechanical viability and good flexibility NBR rubber foam is widely used in manufacturing gaskets and seals for several industries that includes automotive, aerospace etc. It is these characteristics which make it so versatile, allowing manufacturers to use for their specific requirement.

There are many factors to consider when selecting the right NBR rubber foam for your specific needs. Foam comes in many varieties, each of which might be suitable for certain applications. This should not be limited to factor such as how hot or cold your work space may get, but also what temperature range you will require for a application. Additionally, think about the pliability of the foam you require for your upholstering task. Also, when considering the appropriate level of chemical resistance that may be required as this can have a significant impact on how well perfoming in foam will function to certain environments.